Smart systems are increasingly being used in industrial applications in order to make them more effective and cost efficient. The technologies that are used are now able to take the place of more traditional methods, creating more productive environments and saving businesses money.

Accurate Positioning

One of these types of products is a smart electromechanical numerical joining system that has been developed by Kistler. This includes a rotary encoder and a piezoelectric force sensor that is able to accurately measure, as well as control the position. Through a link, the actuator is connected to a programme and monitor unit and a servo controller.

The inclusion of a smart system such as this has many benefits for a company, including the ability to specify particular speeds and positions, as well as clearly marking out the fit process. The amount of flexibility and control that is provided through this new generation of smart systems is far more effective than that given by pneumatic or hydraulic systems.

The area where these smart systems really start to shine is in environments where it is vital to have accurate positioning. An electromechanical joining system offers many advantages when compared with the traditional joining modules and hydraulic presses, mainly due to the more precise measuring and controlling of the position that can be achieved, which results in a higher degree of accuracy.

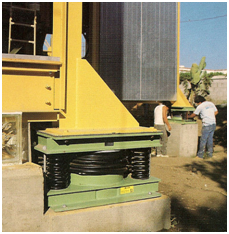

Smart Damping Systems

Another application where smart systems are increasingly being used is in damping, where smart Proportional Integral Derivative (PID) systems are used along with electrorheological fluid (ERF) technology.

Here systems can provide electronically adjusted dampers that can react in a matter of milliseconds. These can be used along with traditional components such as a ductwork blast gate damper and other parts available from suppliers like http://www.dustspares.co.uk/Blast-Gate-Damper.html. This enables damping to be controlled through a range of digital elements and these systems are maintenance free once in operation, as they include no moving parts.

The use of intelligent dampers brings about a number of key benefits, including remote control signals, enhanced efficiency, durability, silent acoustics, the ability to control systems with high frequencies and continuous force.

As technology moves further forward these smart systems will be used more frequently to improve efficiencies over an extensive range of applications, from automated handling equipment to production machinery.