With any type of transformer there is a degree of inefficiency inherent in the system, leading to a certain amount of power loss. Whilst these inefficiencies can’t ever be eliminated entirely, it is possible to reduce them through effective design.

There are two types of loss in transformers. These are load losses, caused by resistance in the coils which vary according to how hard the transformer is working, and no-load losses, which are caused by the current needed to power the core. These losses are constant regardless of load.

Why Toroids?

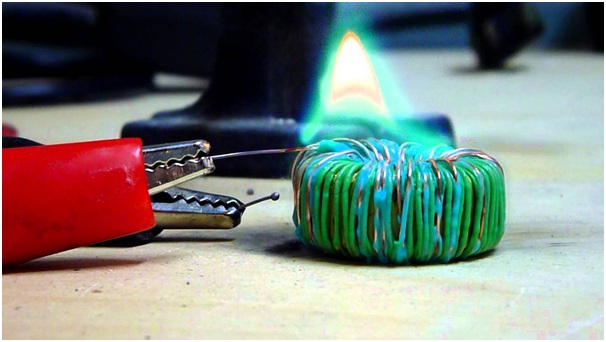

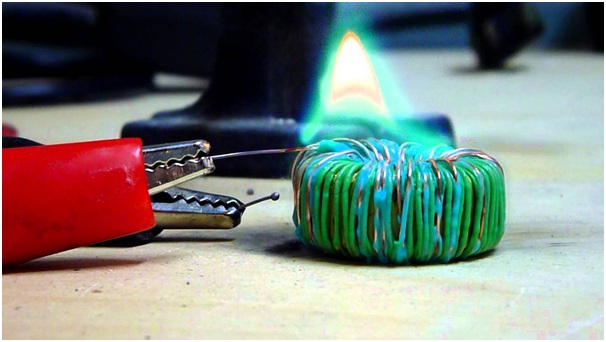

One of the more efficient designs is the toroidal transformer. Not only does this type of design save energy in use, but it takes less material to manufacture both the cores and the conductors. This is because both the primary and secondary windings of the transformer are placed on top of each other. This brings an added advantage that the transformers themselves can be made smaller too, allowing them to be installed in situations where space is at a premium and a conventional transformer may compromise the design.

This has the effect of reducing the voltage drop under load, and it cuts the amount of stray magnetic field. A toroidal design therefore is less likely to interfere with other devices nearby and emits minimal hum. The additional quietness is important for use in situations where background noise is a nuisance – recording studios or laboratories, for example.

Although they have many advantages, toroid designs are more difficult to manufacture, especially at larger sizes, as the winding of the core is a more complex and labour-intensive process.

Uses of Toroids

High -powered toroids from companies like http://sigatransformers.co.uk/ are used in a variety of transformer applications. These include inverters for wind and solar energy systems, as well as in uninterruptible power supplies for mission-critical systems in computing and healthcare.

They also have transport applications, particularly for rail and marine use. They’re increasingly used on floating docks as sub-stations. Here the advantages of compact size and lower weight that the toroid offers are a big advantage.

They’re becoming common in three-phase applications too. Again, the compact size is a plus as three single-phase transformers can be mounted in a number of different configurations, making them a flexible choice that doesn’t compromise the design of an installation.